When it comes to designing ARM baseboards and carrier boards for systems on modules (SoMs) in challenging environments, you cannot afford to overlook any detail. This process demands not only technical precision but also an understanding of the unique environmental stresses these boards will face. At Interelectronix, we've dedicated years to perfecting this craft, ensuring that every board we design stands up to the harshest conditions, from extreme temperatures to high-vibration settings. Our experience in the field has shown us that it’s not just about surviving the environment; it’s about thriving in it. Let us walk you through the essentials, so you can feel confident that your next project is built on a foundation of resilience and reliability.

Understanding the Essentials of ARM Baseboard Design for SoMs in Challenging Environments

Designing a baseboard for ARM-based systems on modules (SoMs) involves more than just connecting components; it's about crafting a reliable platform that can withstand demanding conditions. One of the primary considerations is the selection of materials. In environments with extreme temperatures, vibrations, or exposure to elements, the materials used must not only endure these conditions but also maintain their integrity over time. This includes choosing the right type of PCB material, connectors, and protective coatings.

The Importance of Material Selection in Harsh Environments

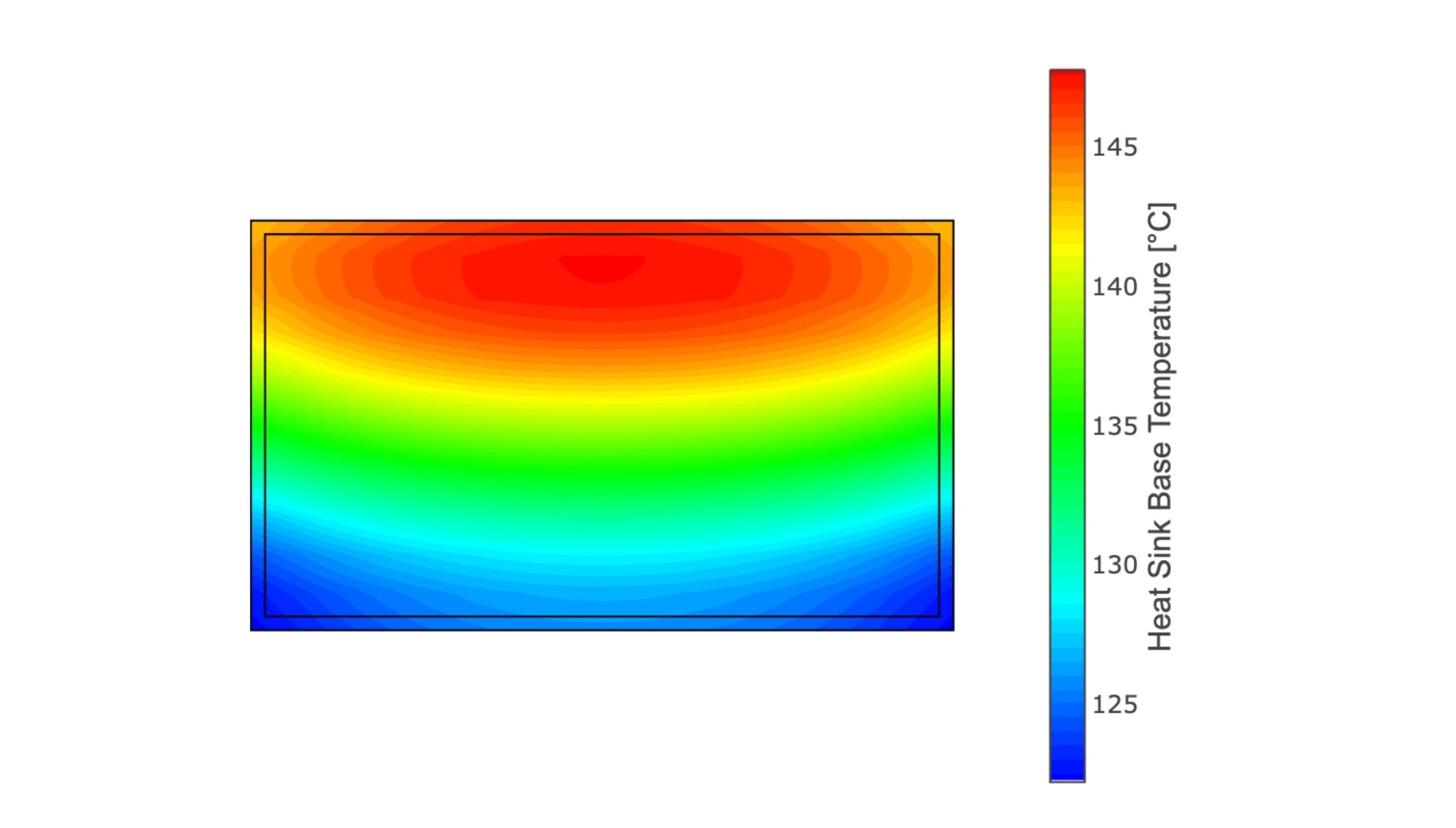

Thermal management is another critical aspect. High-performance components generate significant heat, which can lead to failures if not properly managed. This means incorporating heat sinks, thermal vias, and considering the layout to ensure optimal heat dissipation. Understanding the thermal dynamics of your design and the environment it will operate in is crucial for longevity and performance.

Effective Thermal Management for Longevity and Performance

Vibration and shock resistance are also paramount. In industrial, automotive, or aerospace applications, the baseboard must endure constant movement and shocks. This requires careful design of the mounting mechanisms and the use of components that can withstand such stresses. Reinforced solder joints and flexible PCB designs can mitigate the risks associated with mechanical stresses.

Enhancing Vibration and Shock Resistance

Power supply design cannot be overlooked. A stable and reliable power supply is vital for the consistent operation of ARM-based systems. This involves not only ensuring that the power requirements of all components are met but also protecting against power surges and electrical noise. Using high-quality capacitors, inductors, and designing effective power distribution networks are essential steps.

Ensuring Stable and Reliable Power Supply

Environmental protection is another layer of complexity. For outdoor or harsh industrial environments, the baseboard might need protection from dust, moisture, and chemical exposure. Enclosures with appropriate ingress protection (IP) ratings, conformal coatings, and gaskets can provide the necessary defense against these elements.

Comprehensive Environmental Protection

Moreover, signal integrity must be maintained across the board. High-speed signals can degrade due to electromagnetic interference (EMI) or poor layout practices. Ensuring proper grounding, shielding, and careful routing of high-speed traces are critical to maintaining signal integrity. Utilizing differential pairs and controlled impedance traces can help mitigate issues related to signal degradation.

Maintaining Signal Integrity in High-Speed Designs

Software integration and testing also play a vital role in the development process. Ensuring that the firmware and drivers are well-optimized for the hardware can prevent many issues down the line. Rigorous testing in simulated environmental conditions can help identify potential points of failure before deployment, saving time and resources in the long run.

The Role of Software Integration and Testing

In summary, designing ARM baseboards for systems on modules in challenging environments requires a comprehensive approach that considers material selection, thermal management, vibration resistance, power supply stability, environmental protection, and signal integrity. Each of these elements must be meticulously planned and executed to ensure the final product is robust, reliable, and capable of performing under the harshest conditions.

Conclusion: Partner with Interelectronix for Reliable and Robust Designs

At Interelectronix, we understand these challenges and have the expertise to guide you through the process. Our extensive experience in designing for harsh environments ensures that we can help you create a solution that not only meets but exceeds your expectations. Contact us today to learn more about how we can assist with your next project and ensure its success.