TOPPAN FORMS CO., LTD. Develops Advanced Printed Microwire Technology

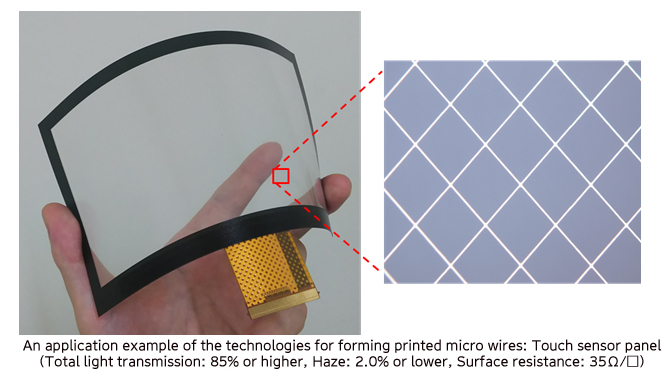

TOPPAN FORMS CO., LTD., based in Tokyo (Japan), has recently developed a technology for the production of printed microwires that is suitable, for example, for use in touch sensor panels. This innovation represents a significant advancement in the field of printed electronics and is poised to have a considerable impact on the industry.

Transparent electrodes

The newly developed technology combines conductive ink with a specialized printing process to produce microwires that are just 4μm (micrometer) wide. These microwires, made from silver salt ink, serve as transparent electrodes, offering a superior alternative to the previously used Indium Tin Oxide (ITO). This makes them ideal for integration into devices with wearable sensors, IoT sensors, and touch panel sensors. The reduction in the size of these microwires from the conventional 10μm to 4μm is a crucial development. This smaller size meets the growing demand for increased power efficiency, reduced dimensions, and enhanced functionality in modern electronic devices.

The unique aspect of this new manufacturing process is the ability to create microwires that are just 4μm wide, a significant improvement over conventional printing technology processes like photographic development, which typically produce wires about 10μm wide. The larger size of these traditional wires is becoming increasingly unsustainable due to the rising demand for more power, smaller dimensions, and new functionalities. The new, more environmentally friendly manufacturing process developed by TOPPAN FORMS CO., LTD. addresses these challenges effectively.

5 Reasons to Choose Silver Salt Ink

- Microwires (width: 4μm) can be produced by printing: The new technology allows for the production of extremely fine microwires through a printing process, which was not possible with previous technologies.

- The new ink allows continuous printing on a practical level: This means that the production process can be scaled up efficiently, making it viable for large-scale manufacturing.

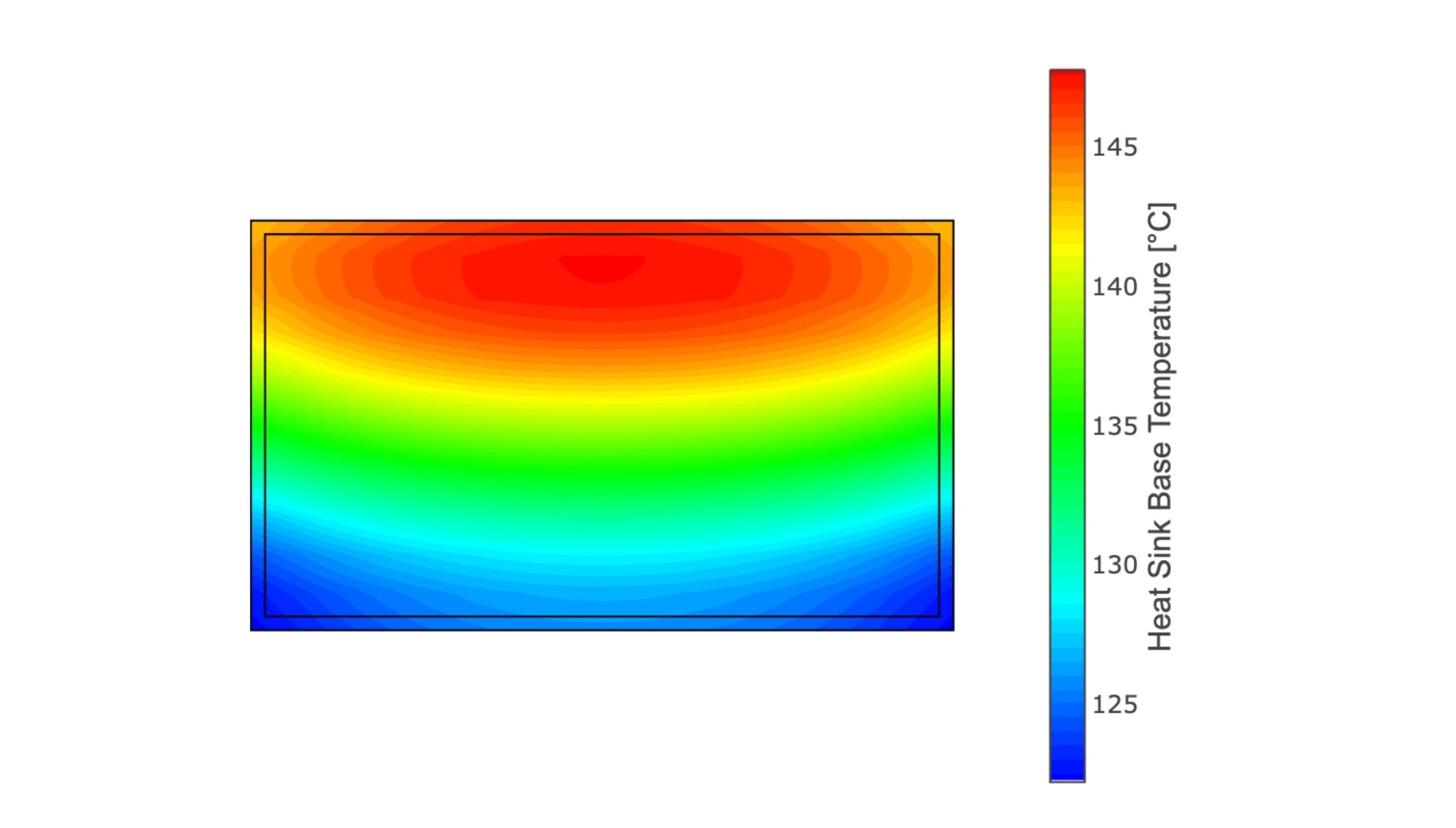

- Enables wiring on thinner foils (with a thickness of about 100nm) with superior conductivity: The new ink can be used on very thin foils, providing excellent conductivity with a volume resistance of 7μΩ-cm, compared to ITO's 150 to 300μΩ-cm. This significant improvement in conductivity enhances the performance of electronic devices.

- Capable of forming wires on plastic base materials with low heat resistance (such as polycarbonate): The technology is versatile enough to be used on various base materials, including those that are sensitive to heat, expanding the range of possible applications.

- Resistant to electrochemical migration at a practical level: Electrochemical migration is a common issue in silver wiring, but the new technology has mitigated this risk, ensuring the durability and reliability of the printed microwires.

This new development by TOPPAN FORMS CO., LTD. is set to revolutionize the production of transparent electrodes and has broad implications for the future of printed electronics. The combination of smaller microwire size, improved conductivity, and environmental benefits positions this technology as a significant advancement in the industry.