The optical bonding (optical bonding = transparent liquid bonding) of one or more layers of glass on the back of a touchscreen increases its impact resistance and reduces light reflection. Such touchscreens are particularly interesting for outdoor use. Because you are almost vandal-proof. But increased safety and splinter protection are also required in the industrial environment. Optical bonding is also used here.

We briefly show you the most important advantages of optical bonding

Touchscreens with optical bonding

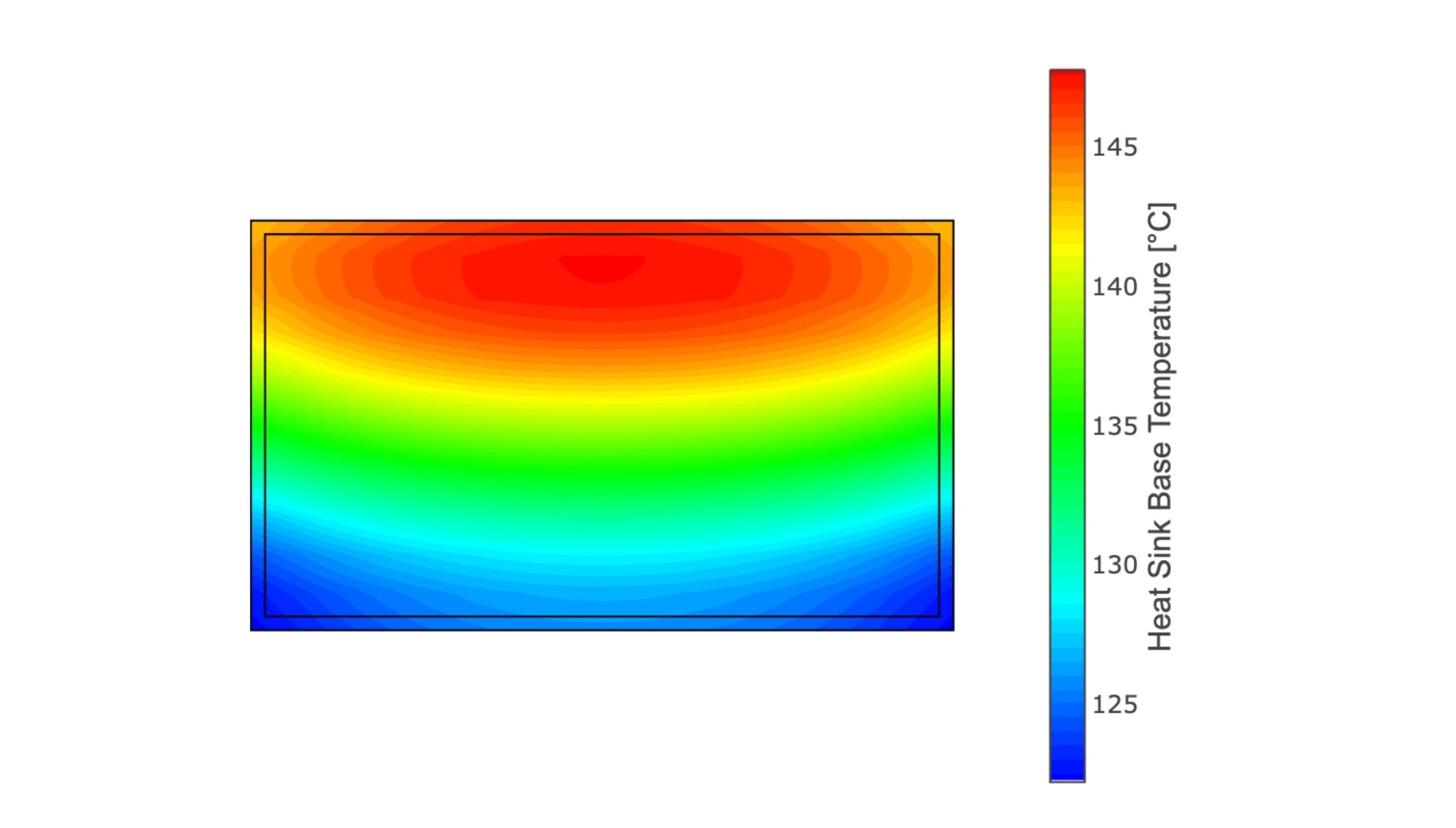

- Have a longer service life. This is because the air gap between the glass panes is closed. As a result, heat dissipation to the outside is better.

- are more robust. This is because bonded displays are more stable, especially under heavy mechanical stress.

- provide less reflection from solar radiation. Since the refraction of light is reduced by gluing. The contrast is also stronger than without optical bonding. So the display is easier to read. Power consumption is reduced.

- Provide a better optics. The user will thank you for it.

- Reduce condensation. This is because the air gap between the panes, the glass and the display disappears. This prevents moisture from penetrating from the outside, which can settle.

- can be mounted dust-free in the clean room. This prevents optical interference from dust particles.

By the way, the robustness of touchscreens with optical bonding can be checked by means of a ball drop test. In this way, it can be ensured that glasses treated in this way are also suitable for industrial use (medicine, manufacturing, transport, etc.).