Not only does glass look good, but it is also usually less sensitive and clearer than plastic surfaces. And the fact that glass is inevitably fragile has been confirmed as an untenable prejudice at least since Steve Jobs came onto the market with his first iPad.

More and more portable tablet PCs and smartphones have been equipped with touchscreen surfaces made of glass in recent years. Which, by the way, are made extremely hard and much more scratch-resistant by means of chemical processes.

Glass looks noble and valuable

Glass touchscreens are not only popular in consumer electronics. In the industrial environment, too, there is an increasing emphasis on robust, innovative and universally operable touch surfaces that have a chance of survival even in a harsh working environment.

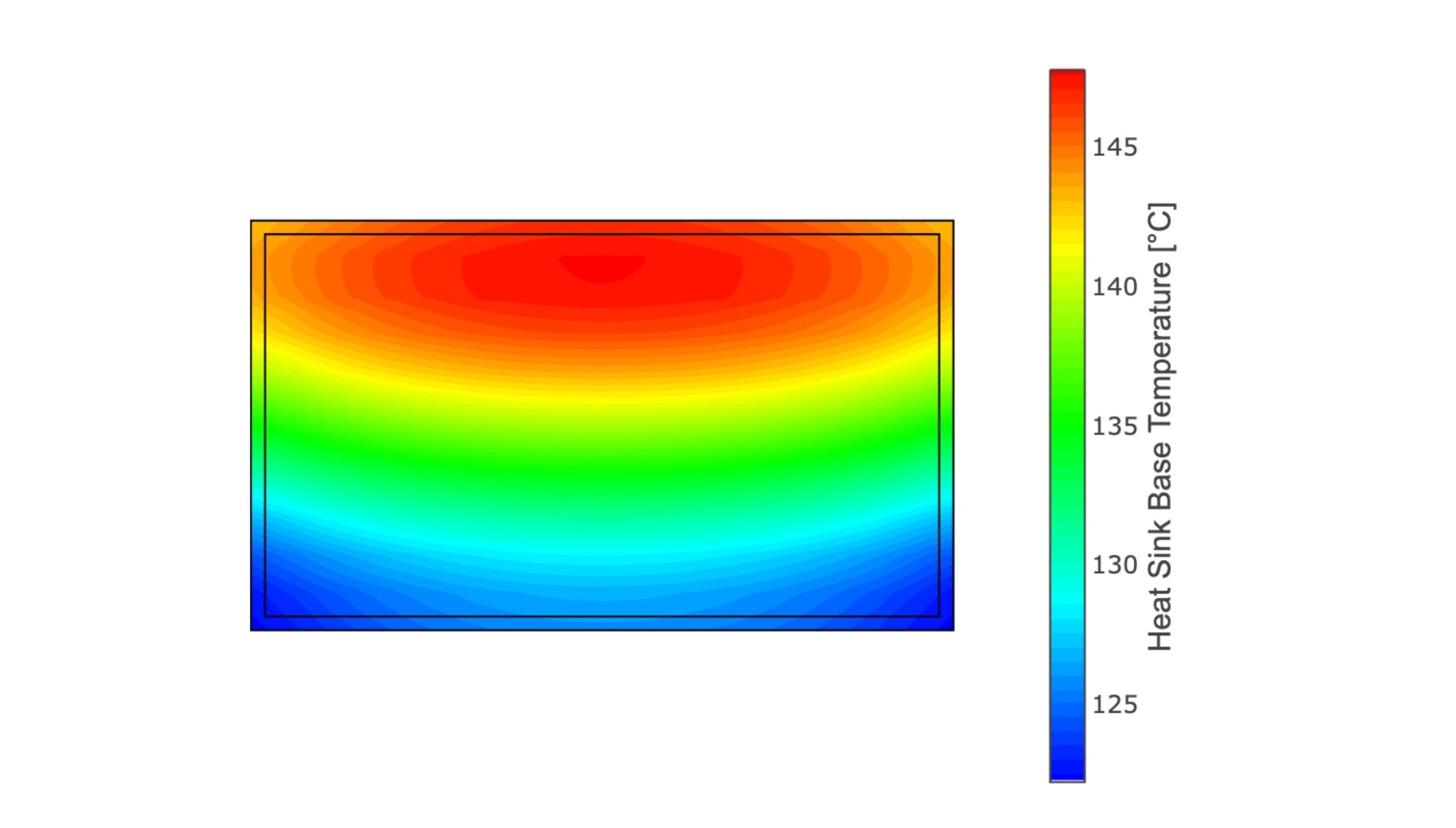

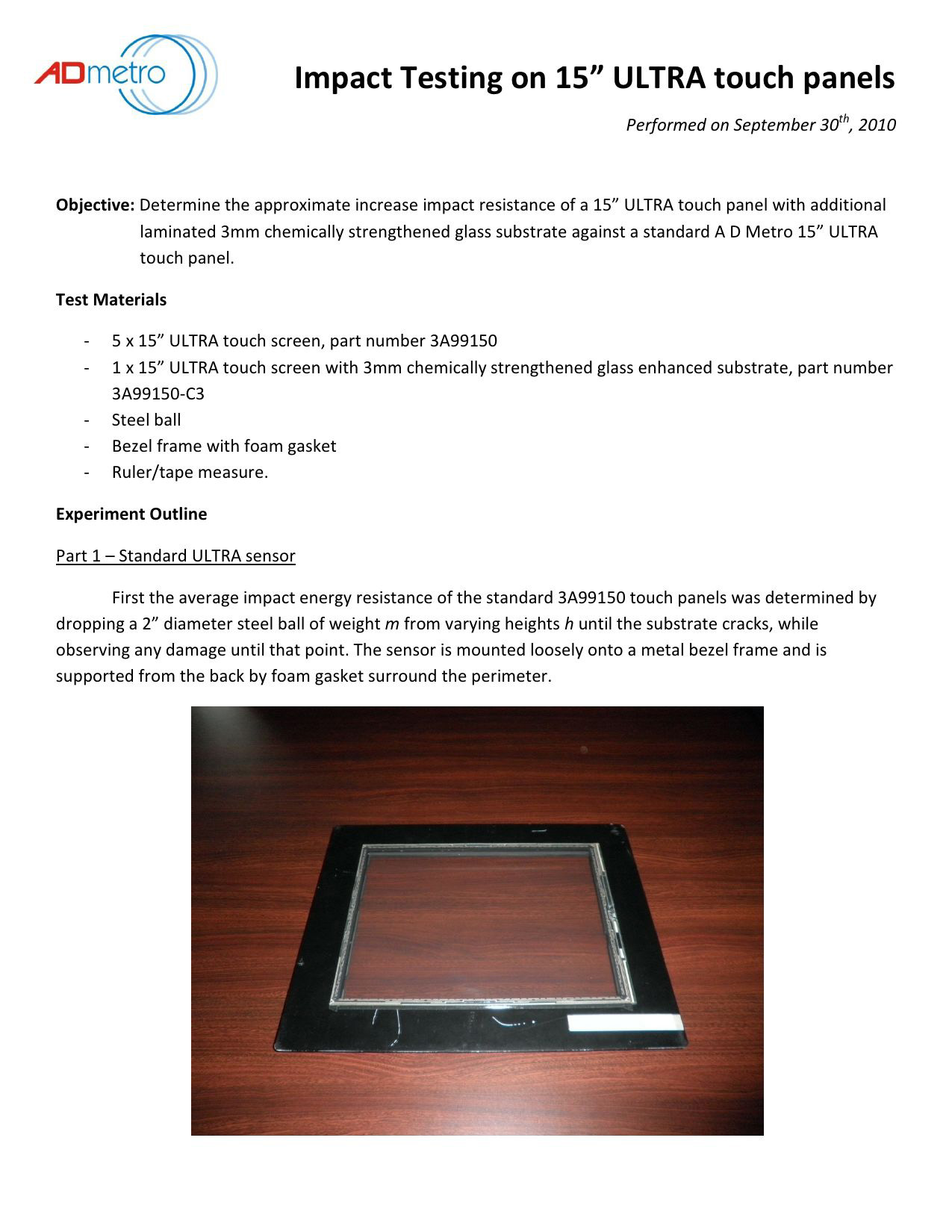

Ball drop test

We also tested the impact resistance of glass and wanted to see how robust 3 mm chemically tempered glass can actually be. An approx. 500g heavy and 2" thick steel ball was used, which we dropped from different heights (between 55 - 250 cm) onto a touchscreen. So much in advance: we were more than satisfied with the result.

The result of our ball drop test is available in our download area.

In summary, customers from different industries cannot go wrong with our multi-touch PCAP touch screens. This is because they achieve very good results in terms of resistance and durability with chemically hardened substrate glass surfaces.

Depending on your needs, we offer further customer-specific tests, which are carried out in accordance with the following standards:

- DIN/ISO 6272-2 for the verification of indirect impact deepening

- ISO 6272-1 for the test of direct impact deepening.