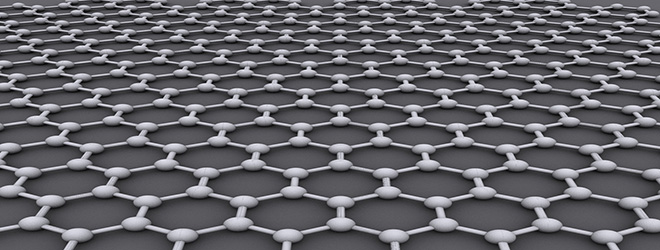

We have often reported that graphene is one of the hardest and most resilient materials in the world. Graphene is a chemical relative of diamonds, coal or the graphite of pencil leads - only better.

It is also called a "miracle material" by some people, because with only one atomic layer, it is one of the thinnest materials in the universe – less than a millionth of a millimeter thick. It has enormous economic potential due to its many advantages and could be used in the future for the production of solar cells, displays and microchips.

For example, instead of the indium-based materials used today, graphene could revolutionize liquid crystal displays (LCDs) used in flat panel displays, monitors and mobile phones.

There are different types of graphene, which also require different manufacturing techniques. In this article, we will briefly introduce you to the different types of graphenes.

Monolayer Graphene

Monolayer graphene is the purest form of graphene. It consists of a 2D hexagonal lattice of carbon atoms.

Few-layer Graphene (FLG) or Multi-layer Graphene (MLG)

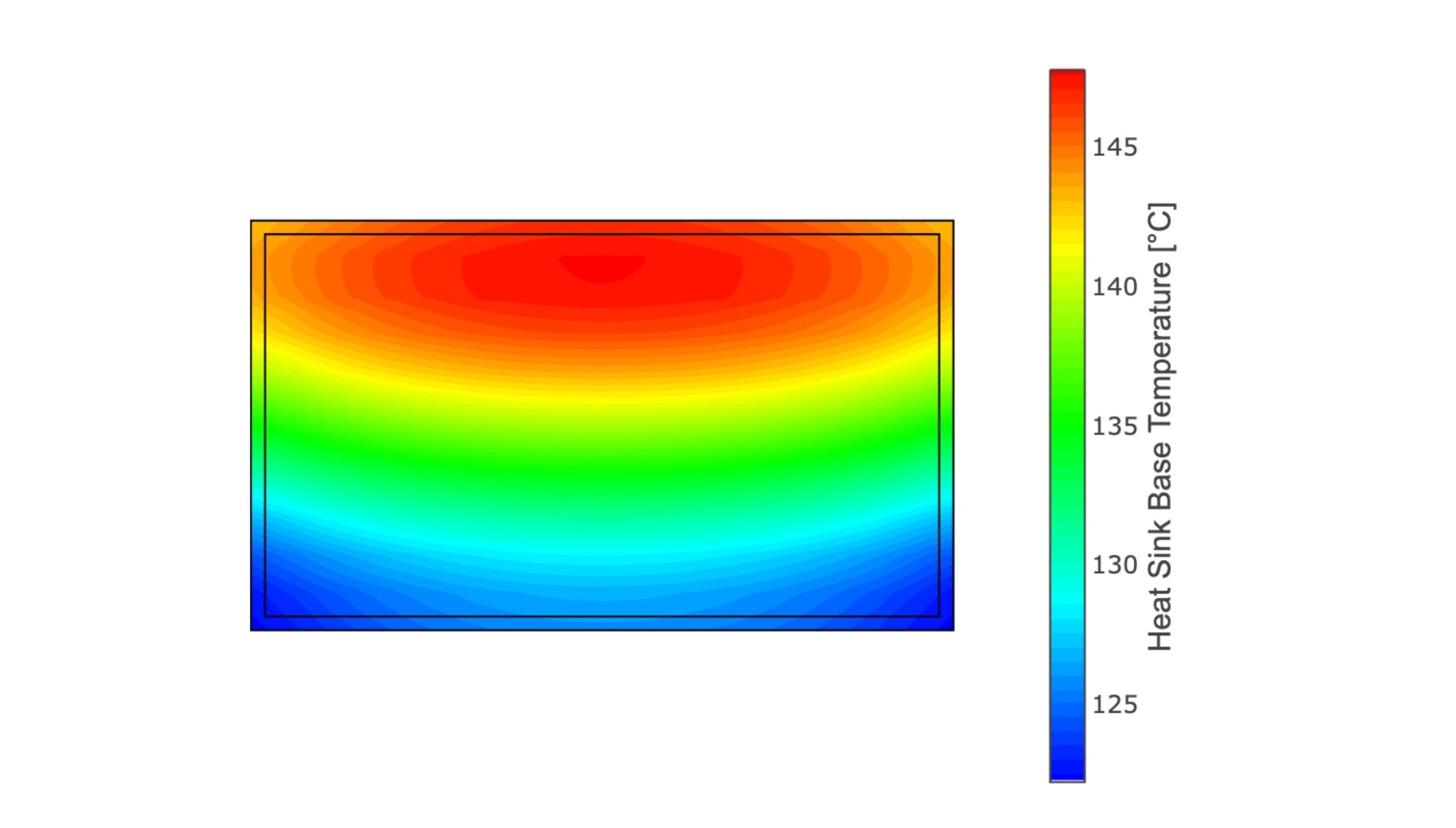

These are simply several layers of graphene layers. The more layers of graphene there are, the more the thermal conductivity decreases. MLG is suitable as a composite material and as a mechanical reinforcement.

Graphene Oxide (GO)

Graphene oxide is synthesized from graphite powder by a modified Hummers process. It is particularly suitable for use in flexible electronics, liquid crystal devices, chemical sensors and as an indium tin oxide replacement, especially for touchscreen devices.

Reduced Graphene Oxide (rGO)

Reduced graphene oxide (rGO) is ideal for conductive inks. It is produced similarly to graphene oxide.

Graphite Oxide

Graphite oxide is a precursor of graphene oxide (GO). It used to be called graphitic acid. It can be obtained from graphite under the action of strong oxidants. In the 2000s, graphite oxide became interesting as a possible precursor for the production of graphene.

Graphite Nanoplatelets, Graphite Nanosheets, Graphite Nanoflakes

Graphite nanoplatelets, graphite nanolayers, and graphite nanoflakes are 2D graphite materials with a thickness and/or transverse dimension of less than 100 nanometers. They are ideally suited for electrically conductive composite materials.

Production methods

Due to the rapidly growing interest in graphene, the development has produced a whole range of different manufacturing methods. The most important synthesis processes of graphene include:

- Reduction of graphene oxide

- Chemical and mechanical exfoliation

- Chemical vapor deposition (CVD)

- Epitaxial growth on silicon carbide